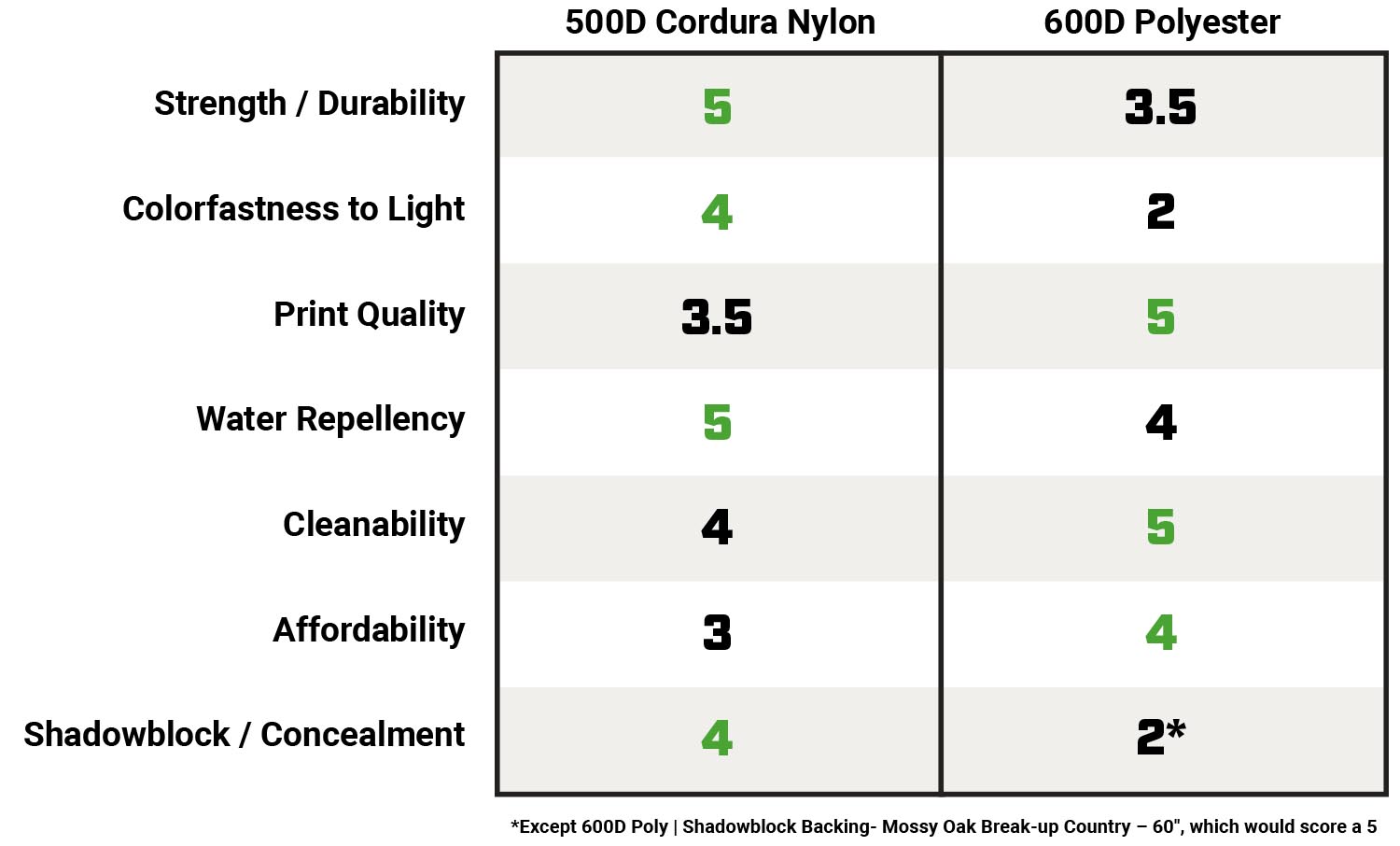

We have received many questions regarding the differences between 500D Cordura Nylon and 600D Polyester. I have put together a diagram and some supporting information to help better explain the differences between these two fantastic fabrics. Both the 500D Nylon and the 600D Polyester fabrics are great performers for hunting & outdoor projects. Hopefully the diagram below helps explain the differences.

Fabric Strength

The Cordura name is synonymous with ruggedness and strength so it scores a 5 out of 5 in our scale. Nylon is typically a stronger fiber than polyester and the 500D Nylon is no exception. However, the 600D Poly Oxford fabric is a very versatile as well. This fabric weighs nearly the same as the 500D Cordura Nylon and is used for rugged, durable products ranging from backpacks, camping chairs and hunting blinds. When fabric strength is important, our 500D Cordura Nylon is definitely stronger than the 600D Poly but they are both good choices for a strong solution.

Print Colorfastness

The 500D Cordura® Nylon scores better here due to the fact it is pigment printed instead of transfer printed. It might not look as nice, but it will definitely do better against the sun’s UV rays than the transfer printed poly will. 600D Poly Oxford is transfer printed and tends to fade faster in direct sunlight.

Print Quality

As mentioned above, the 600D polyester fabric utilizes transfer printing that achieves stunning detail and image quality. Together with the smooth print surface of the polyester, it produces an almost photographic image. This earns it a full 2 point advantage over the 500D nylon. The pigment printed nylon looks great – but the textured surface of the nylon fabric along with the pigment printing tend to give it more rugged and less defined print lines.

Water Repellency

Both fabrics come equipped with DWR (Durable Water Repellency) and PU coating on the back. This is the industry standard for waterproofing outdoor fabrics. The 500D Cordura scores slightly higher because of it receiving a 2 pass PU coating (thicker) where the 600D polyester receives a 1 pass. When it’s all said and done, this doesn’t make a whole lot of difference, but we have to give a slight edge to the 500D Cordura Nylon here.

Check out our Waterproof Test

Cleanability

Both fabrics are 100% synthetic and have DWR treatment. This makes them both resistant to mold and mildew while allowing them to shed any water-based mess like a true champion. However, as mentioned above, the polyester has a slicker surface than the textured, rugged feel of the nylon. This scores the 600D Polyester a 5 out of 5 on our scale for its ease of cleaning – just dampen a cloth… wipe and go!

Burlap is awful in comparison. These fabrics are perfect for hunting blinds.

Affordability

With all the bells and whistles that come with these fabrics, it comes as no surprise they are towards the higher end of our fabric pricing range. They’re going to run a little more than, say, cotton t-shirt fabric. However, the old adage “you get what you pay for” applies here as much as anywhere. These fabrics are constructed to take abuse. They will last longer and perform outdoors brilliantly. The 500D Cordura Nylon, with the extra strength characteristics, costs about 25% more than the 600D polyester.

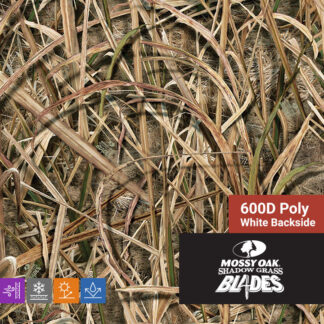

Shadowblock / Concealment

The 600D Poly and 500D Cordura Nylon are both tightly woven and built similarly. We’re giving the edge here to the 500D Cordura because it’s a little bulkier, thicker and has the extra PU coating on it. Plus, the back of the nylon fabric tends to have a little bit of the camo print “bleed through” where the back of the 600D Poly fabric is just plain white. One exception to this – the 600D Poly | Shadowblock Backing- Mossy Oak Break-up Country – 60″ has a shadowblocking black PU coating. This is the ultimate fabric to hide you and to keep your shadows hidden on a sunny morning.

I lean toward 660d poly for a duck blind but I have to do something for the reverse side. White is not good. Is there a way of painting the fabric to get rid of the white color? Have you any other suggestion? Unfortunately mossy oak break-up country won’t do the trick for me.

Hi Marc,

Thanks for contacting us. You are correct about the 600D poly – most of it comes with a white back. I think your reference to Country was about the 600D that has the black (shadowblock) backing. Just for your info, I have also recently added Mossy Oak New Break-Up with Shadowblock backing to Camo Depot, as well. So, you have two patterns to choose from.

Regarding the best way to cover the white backing – I’ll be honest – I’m not sure if painting would work or not. I am guessing that a solvent based spray paint would work at least on a temporary basis. Do not use a water based paint, as the water repellency added to the fabric would likely keep this from sticking. The recommended way to cover the white back would be to add an inexpensive backing fabric to it. But, if you do decide to paint it, please let me know how it turns out.

Good luck on this Marc. Let me know if any other ?’s

tks!

Would you use your fabric to change a a bimini top?

HI Josh – two fabrics would serve the purpose fairly well – 600D poly and 500D nylon. They’d be perfectly water resistant and strong enough to handle the task. The only issue I think you might run into is fading of the print. The go-to fabrics for Bimini tops are usually solution dyed, which isn’t really doable for camouflage. So, you’d have a great looking and unique Bimini top, but should expect the print to fade. How fast just depends on numerous things – your location, how many hours of sunlight it’s exposed to and what time of day it’s exposed.

I don’t know for sure if any of our customers have used this fabric for this purpose or not, but I do know it has been used many times for recovering boat seats and benches. This would seem to face similar exposure and I haven’t had complaints about it – just FYI.

If you want to go ahead with this, I’d probably recommend the 500D Cordura nylon for this. The print will hold up much longer than the polyester.

Good luck and please get back to us with your review of the fabric if you go ahead with this. Would love to hear if you would recommend it for this!

EL tejido cordura se puede imprimir con sublimación?

Do you also print patterns, such as custom printing from patterns that we design? I have several patterns that I have designed and would like to produce items from textiles with my designed pattern.

Thank you,

NORBERT KAUSEN CD

Hi. Sorry, we are not commercializing new patterns at this time. Please check back with us in the near future and best of luck with your pattern development!

Do you suggest 500d for 26 pound weight vest?

Yes, I would recommend the 500D nylon for a weight vest. It’s going to have better break and tear strength over the 600D polyester fabric. Should make for a durable and good looking product when you are done!

Would like to know what one yard of Mossy Oak Shadow Grass Blades 500D Cordura Nylon Fabric weights?

Also, what is the color on the back of Mossy Oak Shadow Grass Blades 500D Cordura Nylon Fabric.

The 500D nylon weighs averages 8-9osy, so a little under one pound per linear yard. This is approx value, as the weight can fluctuate. The back of the 500D nylon looks very much like the front. The print bleeds through to the back. It’s a little ghosted but still shows a good image of the camo pattern.

What would the thickness of say 600D be? I am making a seat for hunting this would be a hammock type seat. Or an expanding frame chair. Looking to see if this could be sewn in a loop around a piece of tube

600D poly is perfect for this application. It is durable, yet easy to work with and plenty flexible enough to bend into a loop around a piece of tubing.

I am looking to make an extended top for a duck hunting boat blind, needing it waterproof and wind proof. I’ve looked at the 500D mossy oak bottomland and the 600D mossy oak breakup shadow blocking back.

1) what color is the backing on the 500D bottomland? I can’t have it white.

2) which of the two fabrics would be best to use as a top for a boat blind? Preferably the most waterproof and windproof.

Thanks!

All of the 500D Cordura has print bleed through, so the back of the fabric has a good image of the same camo print as the face side. It’s slightly ghosted and there is a slight sheen from the PU coating, but it’s effectively camo printed on both sides.

Both the 600D poly and 500D nylon are considered windproof and waterproof. The 500D Cordura nylon is a stronger fabric though.

Hope this helps!